Select brand and country

Select language

Contact us

Search

Converting Customized adhesive solutions – as die-cut parts or cross-wound spools

Everything from a single source Quality materials and development expertise

Our versatile range of technical adhesive tapes is the result of extensive expertise and decades of close collaboration with customers across many industries.

Thanks to this broad product portfolio and our in-house converting capabilities, we are able to produce customized die-cut parts and level-wound spools from a wide variety of materials, material combinations, and with diverse properties.

Stronger together

We not only customize and refine our products in-house at our facility – we are also part of an international network of selected converting specialists. This enables us to be present in all major markets, right where our customers are.

This means:

- comprehensive know-how,

- large capacities,

- short delivery times, and

- consistent quality – always and everywhere.

Adhesive bonding – a joining technology with major advantages

Customer-specific adhesive components have proven to be the most effective solution in many industries when it comes to permanently joining materials and functional parts.

Our customized solutions are:

- cost-efficient,

- highly flexible and adaptable,

- efficient in production,

- easily scalable, and

- supportive of automation in your production and logistics processes.

We look forward to your inquiry.

Your Contact person Customized adhesive solutions

For your individual requirements Applications and customization

We produce and deliver our adhesive tape solutions precisely for a wide range of applications and optimal further processing.

Applications

- Fastening/holding of all types of components

- Bonding/joining of a wide variety of materials

- Wrapping/separation to protect components, reduce noise, prevent corrosion, compensate for tolerances, or assist assembly

- Sealing/insulating to protect against temperature, dirt, or moisture

Customization

- Die-cut parts: on rolls, on sheets, individual pieces, perforated, with or without finger lift or extended liner; material combinations possible

- Level-wound spools: for automated processing, in long continuous lengths with or without finger lift or extended liner; depending on material, widths from 3 mm to 29 mm on 3” and 6” cores

Converting Competence Center How we support you in product development

As a reliable adhesive tape manufacturer, our experts are always at your side with comprehensive services – from concept design to the production of your custom die-cut parts or level-wound spools.

-

Requirements

Your specific needs are our priority right from the start. We listen carefully, understand your requirements, and provide practical, application-oriented consulting. Together, we select the right materials and transform your ideas into precise CAD drawings.

-

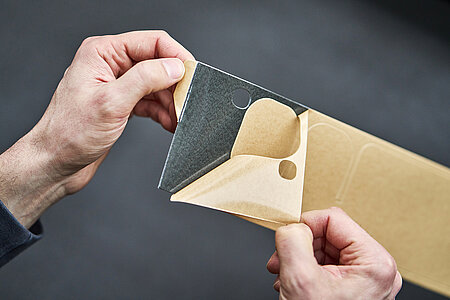

Prototyping

Using laser technology, we produce die-cut samples that you can test in-house before serial production. This ensures your adhesive tape can be optimized and meets all processing requirements.

-

Production

We manufacture the right product for you in small or large series. With our modern machinery, we die-cut, cut, laminate, or spool your adhesive tape. On request, we also advise you on your production setup.

References Successful customer projects

Whether in construction, electronics, household appliances, mechanical and plant engineering, or the mobility sector – we have the know-how to support our customers as straightforward and creative problem solvers.

-

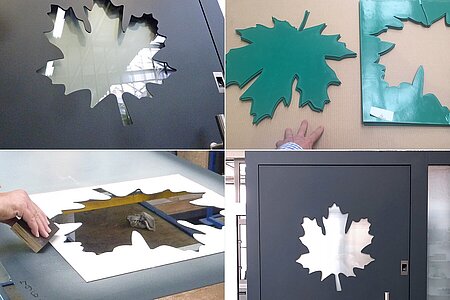

Adhesive solution for a complex design

Even for extraordinary requirements, efficient and reliable adhesive solutions can be realized. For a manufacturer of premium aluminum doors, we developed a fully bonded window in the shape of a maple leaf. The high-performance adhesive tape Coroplast 9920 SPT was used: the product’s flexible acrylic compound compensates for temperature-related stresses between glass and aluminum and can be precisely laser-cut into die-cut parts.

-

Bonding and sealing solutions in mobile applications

In RV construction, adhesive solutions can help reduce costs and simplify processes. For the premium manufacturer MORELO, we developed various bonding and sealing concepts. Handles and cabinets that were previously screwed in place were fixed with adhesive tapes. In the shower cabin, both a tub seal and the permanent bonding of the door lock were implemented.

-

One window – 13 die-cut parts

In the window industry as well, adhesive tape bonding can be the more cost-effective and sustainable alternative compared to screws or rivets. Together with our customer Rehau, we demonstrated this with the “Geneo Inovent” product: this exceptional window, which features a built-in ventilation system hidden in the frame that allows air circulation even when closed, incorporates a total of 13 different bonding and sealing parts.

Your Contact person Customized adhesive solutions